How to Build a Lean-To Shed: Simple Steps for Budget-Friendly Construction

Dreaming of extra storage space without breaking the bank? A lean-to shed is the perfect solution! This simple structure, attached to an existing building like a house or garage, offers a surprisingly spacious addition with minimal cost and effort. This guide provides a step-by-step walkthrough, empowering you to build your own lean-to, saving money and enjoying the satisfaction of a DIY project.

Planning Your Lean-To Shed

Before grabbing your tools, meticulous planning is crucial. Determine the desired dimensions of your shed, considering available space and local building codes. Sketch a simple plan, noting the placement of the door, windows (if any), and the overall layout. This blueprint will act as your guide throughout the construction process. Consider the materials you'll need; a detailed list will prevent costly trips to the hardware store mid-project. Choosing cost-effective materials like pressure-treated lumber and recycled roofing materials significantly reduces the overall cost. Remember to check for any local building permits or regulations you may need to obtain before you begin.

Essential Materials

Gather these key materials before you start:

- Pressure-treated lumber for the frame (posts, beams, rafters)

- Plywood or OSB for sheathing

- Roofing material (e.g., asphalt shingles, metal roofing)

- Concrete blocks or posts for the foundation (if needed)

- Nails, screws, and other fasteners

- Building paper or felt underlayment

- Exterior paint or stain (optional)

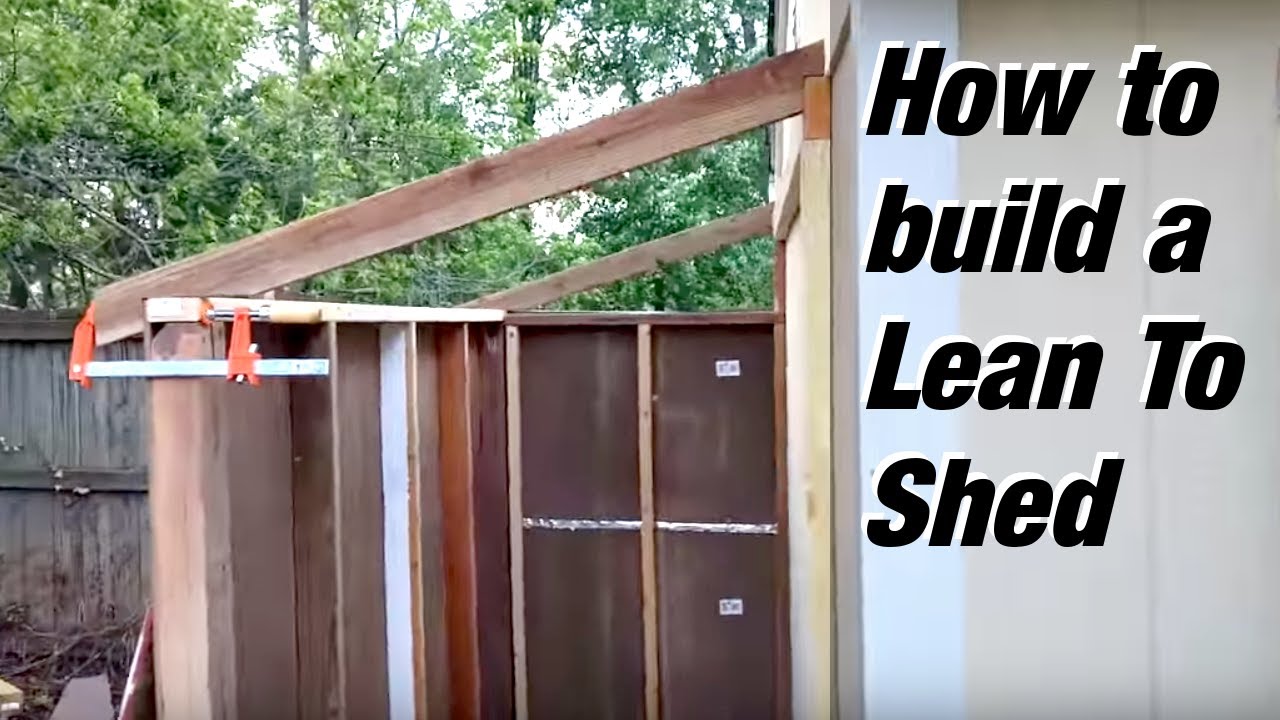

Building the Foundation and Frame

A sturdy foundation is essential for a long-lasting lean-to. For a simple, budget-friendly option, consider using concrete blocks, set in level, compacted ground. Alternatively, you might embed pressure-treated posts directly into the ground, ensuring they're deeply set and properly braced. After completing the foundation, build the frame using your pre-cut lumber. Begin with the base frame, ensuring all corners are square and securely fastened. Then, erect the supporting posts and attach the rafters, ensuring a slight overhang for water runoff. Precise measurements are key at this stage for a well-aligned structure. Use a level frequently to ensure everything is plumb and square.

Securing the Frame

Utilize strong fasteners like galvanized nails or screws to connect the frame components. Consider adding bracing to increase stability, especially if your lean-to is relatively large. Remember, a strong frame is the backbone of a successful project, directly impacting the shed's durability and longevity. Don't rush this step; take your time to ensure the frame is perfectly level and firmly secured.

Sheathing, Roofing, and Finishing Touches

Once the frame is complete, attach the sheathing material (plywood or OSB) to the walls. This creates a solid surface for your roofing material and protects the interior from the elements. Make sure the sheathing is properly fastened, and use building paper or felt underlayment beneath your chosen roofing material to prevent leaks. Install the roofing, carefully following the manufacturer's instructions. Asphalt shingles are a cost-effective and widely available option. Finally, consider adding a simple door and any desired windows. Finish with a coat of exterior paint or stain for weather protection and aesthetic appeal. Remember to secure any electrical wiring according to your local electrical codes if you plan on adding any lights or power to your shed.

Safety First!

Always prioritize safety. Wear appropriate safety gear, including safety glasses and work gloves. Use caution when working with power tools, and be mindful of potential hazards, like uneven ground or sharp objects. If you're unsure about any aspect of the construction process, consult a professional for guidance.

Building your lean-to shed is a rewarding experience. By following these steps, you'll not only gain valuable storage space but also the satisfaction of creating something with your own hands. Remember that patience and attention to detail are key to a successful outcome!

No comments:

Post a Comment

Note: Only a member of this blog may post a comment.