How to Make a Small Pallet Shed: A Complete Step-by-Step Guide

Constructing a small shed from reclaimed pallets offers a cost-effective and environmentally conscious alternative to traditional shed building. This guide provides a comprehensive, step-by-step approach to building a functional and aesthetically pleasing pallet shed, suitable for various storage needs. While requiring some carpentry skills, the project is achievable for dedicated DIY enthusiasts.

Phase 1: Planning and Preparation

Before commencing construction, meticulous planning is crucial for a successful outcome. This phase involves determining the shed's dimensions, selecting appropriate pallets, gathering necessary tools and materials, and securing the necessary permits (where applicable).

1.1 Determining Shed Dimensions and Design

The shed's dimensions should be determined based on the intended storage capacity and available space. Consider the size and quantity of items you intend to store. A simple rectangular design is recommended for beginners, minimizing complexity and maximizing storage space. Sketch a detailed plan indicating the overall dimensions, door location, and window placement (if desired). Consider the height needed to comfortably access stored items.

1.2 Pallet Selection and Preparation

Source high-quality, sturdy pallets. Inspect each pallet for signs of damage, rot, or infestation. Prioritize pallets constructed from pressure-treated lumber, ensuring longevity and resistance to the elements. Clean the pallets thoroughly, removing any debris, nails, or loose boards. Repair any damaged areas using wood glue and screws. Ensure all boards are securely fastened before proceeding to construction.

1.3 Gathering Tools and Materials

Assemble the necessary tools and materials before starting construction. This will streamline the process and prevent interruptions. The following list includes essential items:

- Measuring tape

- Level

- Hammer

- Screwdriver (both Phillips and flathead)

- Drill with various drill bits

- Safety glasses

- Work gloves

- Wood screws (various lengths)

- Wood glue

- Exterior-grade paint or sealant (optional)

- Post anchors or concrete blocks (for base)

- Plywood or OSB (for flooring and roof)

- Hinges and door handle

- Roofing felt or shingles (optional)

1.4 Obtaining Necessary Permits

Check local building codes and regulations to determine if permits are required for the construction of your pallet shed. Contact your local building department for guidance and to submit any required applications. Failure to obtain necessary permits could result in fines or legal repercussions.

Phase 2: Construction

This phase involves assembling the shed's framework, installing the flooring, erecting the walls, and constructing the roof. Careful attention to detail and adherence to the plan are essential for structural integrity.

2.1 Foundation Preparation

Prepare a level foundation for your shed. This can be achieved using concrete blocks, a gravel base, or post anchors set in concrete. Ensure the foundation is sufficiently large to support the shed's weight and is level to prevent structural issues. This is crucial for preventing future problems with the shed’s stability.

2.2 Building the Frame

Assemble the shed's frame using sturdy pallets. Begin by constructing the base frame, attaching pallets together using wood screws and glue. Ensure all corners are square and securely fastened. Once the base is complete, construct the side walls, again using wood screws and glue to attach pallets. Ensure the walls are plumb and vertically aligned. Use additional bracing if necessary to strengthen the structure.

2.3 Installing the Flooring

Install plywood or OSB sheeting to create a solid floor. Cut the sheeting to the appropriate size and secure it to the base frame using screws. Ensure the flooring is level and securely attached to prevent movement or sagging. This layer provides a clean and functional surface inside the shed.

2.4 Erecting the Walls

Attach the side walls to the base frame. Ensure that the walls are plumb and securely fastened using wood screws. Add bracing between the walls and the base frame for additional support. For added strength, consider using additional vertical supports within the wall structure. This will help the shed stand up to the elements and maintain its shape over time.

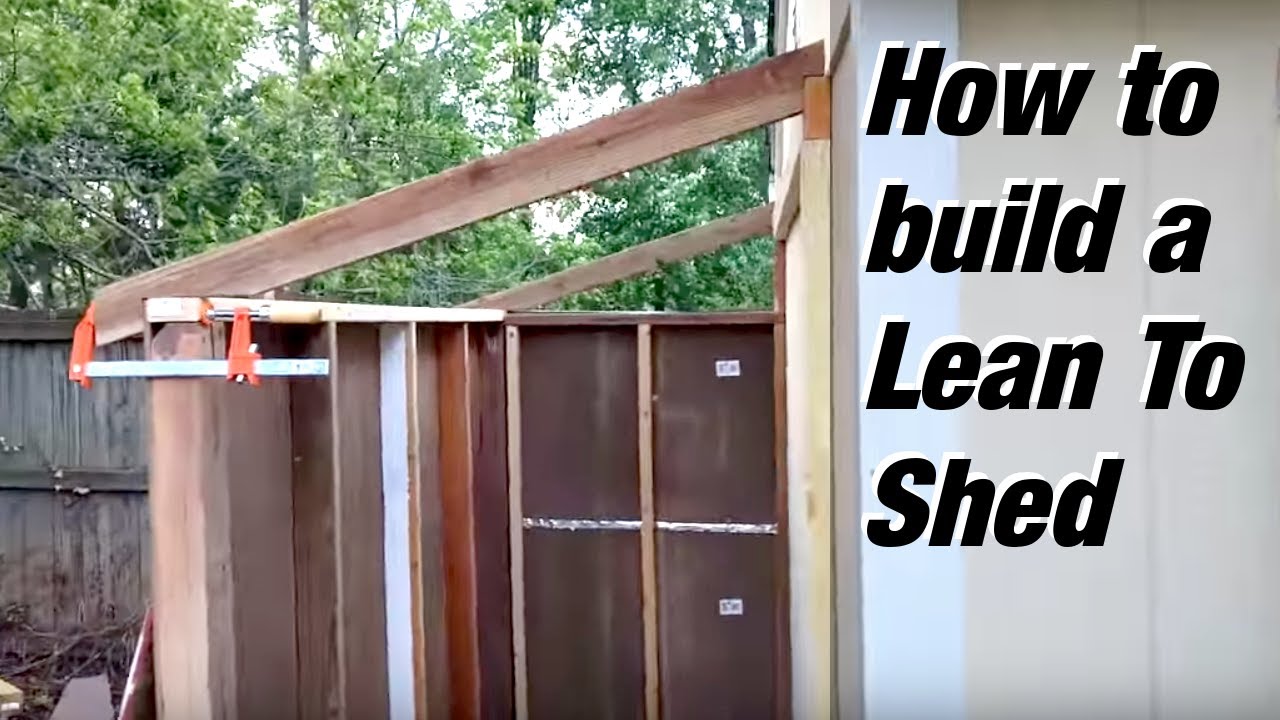

2.5 Constructing the Roof

Construct the roof frame using pallets or lumber. The roof design can be simple, such as a gable or shed roof. Ensure the roof frame is adequately sloped to allow for proper water runoff. Cover the roof frame with plywood or OSB sheeting, followed by roofing felt or shingles (optional) for added weather protection. Secure all roofing materials firmly to prevent damage from wind or rain.

2.6 Installing the Door

Install a door using pre-hung door frame or by creating a frame from pallets. Use hinges and a door handle to create a functional entrance. Ensure the door fits snugly and seals properly to protect the interior from the elements.

Phase 3: Finishing and Refinement

Once the primary construction is complete, this phase involves enhancing the shed's appearance, durability, and functionality.

3.1 Applying Exterior Finish

Apply an exterior-grade paint or sealant to protect the wood from moisture and UV damage. This will enhance the shed's longevity and aesthetic appeal. Choose a weather-resistant finish designed for exterior use. Allow sufficient drying time between coats.

3.2 Adding Finishing Touches

Add finishing touches to personalize the shed, such as adding windows for ventilation and light, installing shelves for storage, or painting the interior walls. These additions enhance both functionality and aesthetics.

3.3 Final Inspection and Cleanup

Conduct a thorough inspection to ensure all components are secure, stable, and properly functioning. Perform any necessary repairs or adjustments. Clean up the work area and dispose of any debris responsibly.

Constructing a small pallet shed requires careful planning, attention to detail, and some carpentry skills. By following this comprehensive guide, you can successfully build a durable and functional storage solution that is both environmentally friendly and budget-conscious. Remember to prioritize safety throughout the construction process.