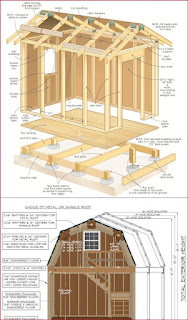

Build Your Dream Garden Shed with Loft: Detailed Blueprints

Dreaming of a spacious garden shed that offers ample storage and a cozy loft? This article provides comprehensive blueprints and guidance to build your own, transforming your outdoor space into a functional and aesthetically pleasing haven. Forget cramped sheds; we’ll guide you through creating a versatile structure perfect for storing tools, gardening supplies, and even creating a relaxing mini-workshop or potting area.

Planning Your Garden Shed with Loft: Size and Layout

Before you grab a hammer, meticulous planning ensures a successful build. First, determine the ideal size for your shed, considering the available space in your garden and your storage needs. A good starting point is to envision how you'll use the space. Will you primarily store tools and equipment? Do you need a dedicated workbench? Or are you hoping for a quiet retreat? This dictates the overall dimensions and internal layout. Sketch a rough floor plan, marking out the positions of windows, doors, and shelves. Remember to factor in the loft’s dimensions, ensuring sufficient headroom and easy access. Accurate measurements are crucial for a perfectly fitting structure.

Essential Considerations for Dimensions

Consider these dimensions as a starting point, but adapt them to your specific needs:

- Overall Shed Dimensions: 8ft x 10ft (this could vary significantly based on your needs)

- Loft Access: A sturdy staircase or a pull-down ladder is essential for safe access.

- Wall Height: Plan for a minimum 7ft wall height to the eaves for ample standing room.

- Loft Height: Aim for at least 4ft of clear headroom in the loft for comfortable use.

Materials List: Sourcing Quality Components

Using high-quality materials directly impacts the longevity and sturdiness of your shed. This list provides a guideline; adjust quantities based on your chosen dimensions. Consider sourcing locally to reduce transportation costs and support your community:

- Pressure-Treated Lumber: For the frame, floor joists, and roof supports. Choose appropriate thickness based on local building codes.

- Plywood Sheeting: For the walls, roof, and floor. Exterior-grade plywood is essential for weather resistance.

- Roofing Material: Asphalt shingles, metal roofing, or even recycled materials are viable options. Choose a material suited to your climate and aesthetic preferences.

- Fasteners: Galvanized nails, screws, and bolts are crucial for a secure structure.

- Windows and Doors: Choose durable options that provide adequate ventilation and security. Consider pre-hung doors and windows for ease of installation.

- Insulation (Optional): If you plan to use the shed year-round or in colder climates, consider adding insulation to the walls and ceiling.

Construction Steps: A Step-by-Step Guide

Constructing your garden shed involves several key stages: Begin by preparing a level foundation. This could be a concrete slab, compacted gravel base, or even treated timber sleepers. Next, erect the shed's frame, ensuring precise alignment and strong connections at every joint. Install the floor joists and plywood sheeting, followed by the wall framing and sheathing. Construct the roof frame and apply your chosen roofing material. Finally, install the windows, doors, and any interior fixtures, such as shelves or a workbench. Remember to check local building codes and regulations throughout the process.

Note: Detailed diagrams and precise measurements are essential for accurate construction. While this article provides a conceptual overview, consulting professional building plans tailored to your specific design and location is highly recommended for a safe and structurally sound shed.

Building your own garden shed with a loft is a rewarding project. By following these guidelines and undertaking thorough planning, you can create a beautiful and functional space that enhances your garden and provides years of valuable storage.